A Complete Guide to Hot Tub Manufacturing & Shipping in China

- Share

- Issue Time

- Jul 29,2025

Summary

Have you ever thought about outsourcing your brand's hot tub (SPA) production to China? Is it a viable option? How do the production processes work for top-quality Chinese hot tub suppliers?

Have you ever thought about outsourcing your brand's hot tub (SPA) production to China? Is it a viable option? How do the production processes work for top-quality Chinese hot tub suppliers?

Many manufacturers in Zhejiang and Guangzhou in China have become long-term partners for some of the world's leading spa brands, handling the production of spa equipment and components.

In this blog, we aim to answer your questions and open a new window for you—allowing you to focus on brand marketing while leaving the manufacturing to the experts, driving true brand growth.

Hot Tub Mold Making in China

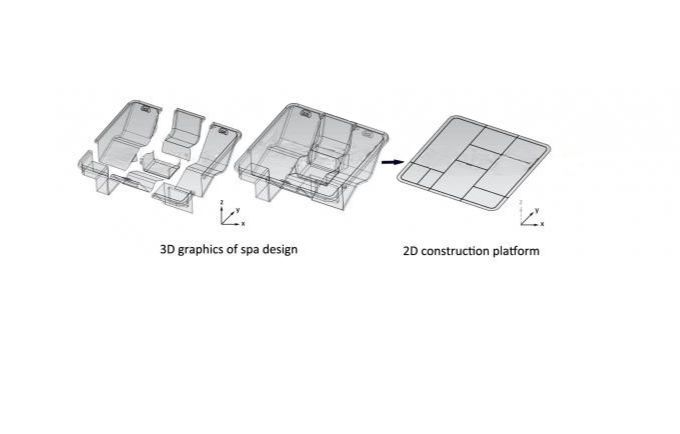

Every spa production begins in the mold department, where molds are created from scratch. The process involves using gel coat for the mold surface, plaster for the base, and plywood for the structure. This entire process typically takes about a month.

Chinese spa manufacturers now have advanced mold-making technology, allowing for customization based on client requirements. During mold confirmation, manufacturers often adjust designs to align with market demands or cultural preferences in different countries.

However, we recommend not underestimating the importance of mold quality. Choosing a supplier with strong mold-making capabilities is crucial. Strict mold production processes and ongoing customer involvement ensure every detail meets the expected standards.

How to Choose the Right Acrylic and Gel Coat Materials?

Acrylic and gel coat are key materials that determine the appearance and durability of a spa. The quality of the acrylic affects the clarity, strength, and longevity of the spa shell, while the gel coat plays a critical role in the surface finish, UV resistance, and abrasion resistance.

Chinese spa manufacturers typically select high-quality acrylic and gel coat materials based on market demand. For example, acrylic used in the U.S. is usually 3.5mm thick, while in China, it's 4.2mm thick.

Low-quality materials can lead to surface scratches, fading, or warping, negatively impacting the user experience and product lifespan. When choosing acrylic and gel coat, it's important to consider the manufacturer's recommendations and market requirements.

Hot Tub Spray Coating Process

Spraying fiberglass and resin is a crucial step in spa production. The three-layer spray coating process significantly strengthens the spa's structure, enhancing its water resistance and corrosion resistance.

Chinese spa manufacturers typically use hand-spraying techniques during this stage, ensuring each layer is applied evenly and securely, preventing cracks or damage during long-term use.

Hot Tub Frame Materials

The frame of a spa is the core structure that supports the entire unit, making it crucial to choose the right frame design and material. In China, the frame materials typically used are:

Standard hot tubs: For regular (non-swimming) spas, the frame is usually made of aluminum. Wood is a more economical option.

Swim spas: For swim spas, the frame is typically made of metal for added strength and stability.

How Custom Features Enhance the Spa Experience?

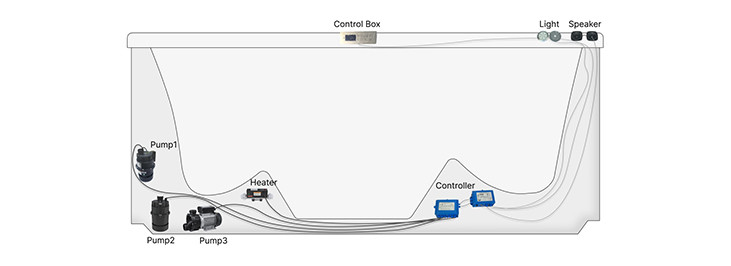

Spa customization is becoming more advanced, offering a variety of functional upgrades. Acrylic panel colors, integrated lighting, speakers, Bluetooth, and other features not only enhance the spa's visual appeal but also improve its entertainment value and comfort.

Chinese spa manufacturers excel in offering customization, providing a wide range of options to meet market needs. Whether it's calming ambient lighting or high-quality sound systems, consumers can tailor their spas to personal preferences.

Caution: When choosing custom features, consider practical usage needs and future maintenance costs. Too many added features may increase the difficulty and cost of repairs, so it's important to make thoughtful choices during customization.

Hot Tub Cleaning and Packaging

After the spa is completed, it undergoes thorough cleaning to remove any internal water and debris. Proper packaging is also essential to prevent damage during transit, ensuring the spa arrives in perfect condition.

Chinese hot tub manufacturers typically use multi-layered protection for packaging, employing foam and wrap materials to safeguard the spa. Proper packaging prevents collisions and pressure during shipping, ensuring the product's safety.

Caution: Inadequate packaging can result in damage during transit. Always ensure the manufacturer uses appropriate packaging materials to prevent damage from improper packing.

Q&A

1.Is the quality of China-made spas really reliable?

It depends on the manufacturer. Reputable Chinese suppliers that follow strict processes — including multi-layer spraying, water pressure testing, and solid engineering — can absolutely meet top international standards. Be cautious of factories that cut corners to offer low prices.

2.What should I focus on when choosing spa components?

Compatibility and quality are key. Mismatched parts can cause installation issues, leaks, performance drops, or even damage the system. Material and workmanship also matter — they affect both durability and user experience. Hydrorelax is dedicated to solving these core concerns.

3.Can spa components be customized?

Yes, Chinese manufacturers offer custom accessory services. You can customize based on your drawings and requirements, though custom molds may require an additional fee.

4.How do I choose the right pump and heater?

Consider the size of your spa and usage needs. Hydrorelax offers a wide range of pumps and heaters to suit different models and market requirements.

Hydrorelax Premium Spa Components: How to Choose the Right one?

With years of industry experience, Hydrorelax understands the different needs across global markets in terms of spa features, styles, and budgets. We offer not only individual parts but also tailored system solutions for your target market.

Our product range covers over 12 major systems, including control systems, hydro massage, heating, lighting, and more — all in one place.

Our expert team recommends the best configurations based on your market standards, voltage, user habits, and usage scenarios (home or commercial). Hydrorelax helps you choose the right parts and boost product competitiveness.

Why Hydrorelax SPA Components Are Worth Trusting?

Hydrorelax components are built to deliver reliable performance and long-term durability. All key components meet international certification standards such as CE, RoHS, and UL, ensuring safety and quality.

They are designed for stable compatibility with mainstream spa systems, reducing the risk of malfunctions and making integration simple and efficient.

With 24 years of experience in the spa industry, Hydrorelax has earned the trust of many top global spa brands. Our components have been tested and proven in markets across Europe and North America, making them a dependable choice for both OEM and distributors.

Feel free to contact us — we believe this could be a great opportunity for your business to grow.