Bulk Sourcing SPA Jets from China: What Worries Buyers Most?

- Share

- Issue Time

- Sep 28,2025

Summary

While low-quality products exist, many Chinese makers have been trusted partners for top spa brands for years.

When sourcing spa jets from China in bulk, what worries you most?

Worried about quality, fragile plastics, or peeling plating?

It's not that.

It's really design flaws, poor fit, leaky seals, or even safety risks from unstable water pressure.

For international buyers,once something goes wrong, it's hard to hold a faraway supplier accountable. That's why 'Made in China' gets a bad rap. But the truth is, while low-quality products exist, many Chinese makers have been trusted partners for top spa brands for years.

Why are there so many low-quality spa jets?

We must first acknowledge that there are indeed a large number of substandard products on the market. Common issues include:

The use of recycled plastic for the outer shell causes the jet to become brittle within a few months.

The electroplated layer is too thin, causing it to bubble or discolor when exposed to water.

Poor sealing of the rubber ring causes water pressure to drop and leaks.

The stainless steel parts actually contain iron, making them prone to rust.

Price pressure. Some buyers chase the lowest quote, and factories cut costs with cheap materials and shortcuts. Prices are low, but so is quality.

Vague specs. Buyers often request a size or material but leave out details like plating thickness or pressure standards. Manufacturers will naturally produce according to their own understanding, which often means trying to save costs as much as possible.

Information gap. Many buyers don't know the production details, giving suppliers room to cut corners without being noticed.

The Real Manufacturing Capabilities of Chinese Factories

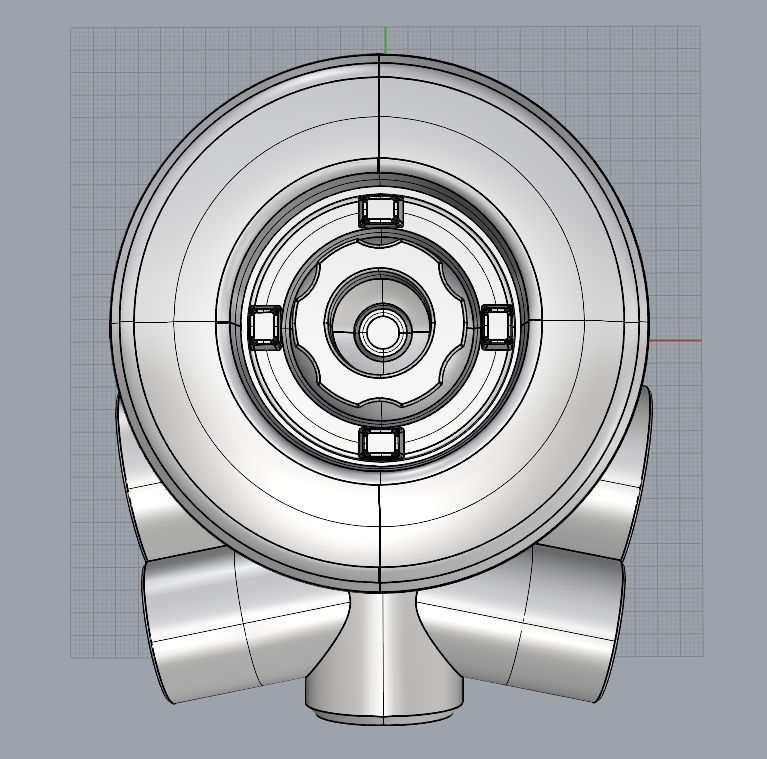

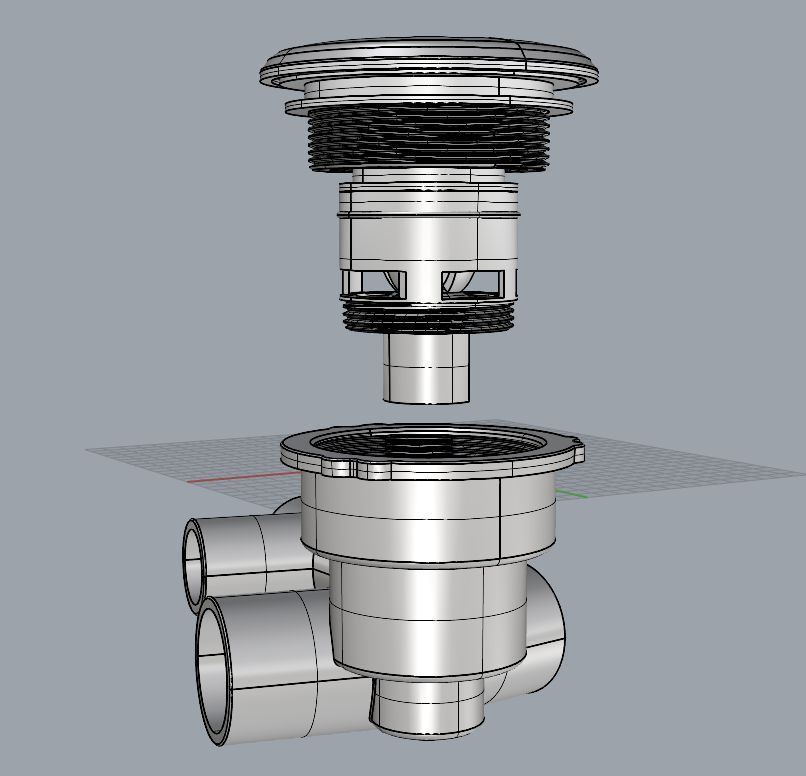

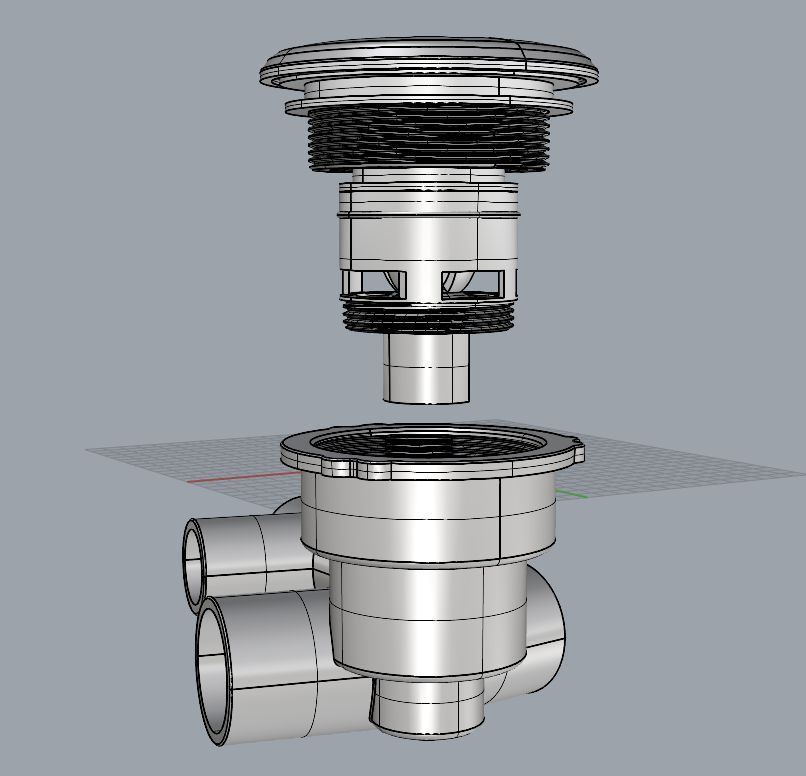

Injection Molding

Premium factories use virgin ABS or PVC+ABS for jet housings, sometimes imported. High-precision molding machines ensure consistent parts with no dimensional errors.

Plating & Surface Treatment

Top factories have automated plating lines with precise thickness control, passing 48–96 hours of salt spray testing. This means coatings can last for years in real spa conditions without discoloring.

Metal Parts Processing

Some Jets have stainless steel parts. High-quality factories use 304 or 316 stainless steel and provide material inspection reports, rather than using cheap chrome-plated iron as a substitute.

Durability Testing

Reputable OEM perform real tests: water pressure, life-cycle (tens of thousands of on/off cycles), and chemical resistance (chlorine, bromine). These are real, not marketing gimmicks.

In other words, can Chinese factories produce high-quality SPA Jets? Absolutely. The question is whether you have found the right manufacturer and implemented effective control methods.

How to Minimize Hot Tub Jet Sourcing Risks

So, what can buyers do to avoid falling into the low-quality trap?

Specify standards

Clearly state requirements in the contract,like use virgin ABS, no recycled plastic.

Sample & test

Always request samples. Check appearance, then run real tests: pressure, chemical resistance, lifespan. Third-party labs are ideal.

Compare multiple suppliers

Even with the same material, workmanship varies. Extremely low quotes should raise a red flag.

Third-party inspection

Before shipment, have an inspection company verify that the bulk order matches the approved sample. It's far cheaper than handling post-sale issues.

Build long-term partnerships

Working with a reliable factory long-term is more stable than switching suppliers constantly. Good factories treat clients as partners and are more willing to maintain quality.

Why Do So Many Top Brands Choose Chinese Factories?

Here's something many new buyers don't realize:

Many well-known spa brands in Europe and North America have their jets made in China.

Products may carry a 'Made in USA' label, but often that just means final assembly happens in the U.S.,the core components come from China.

Some Chinese manufacturers have 10–20 years of OEM experience. They know international standards and hold CE, UPC, NSF, and other certifications, fully meeting Western market requirements.

If you're considering bulk sourcing hot tub jets or other hot tub components from China, the real question isn't whether China can produce them, but whether you can choose the right factory and control the process.

Yes, low-quality products exist, but they cater to buyers chasing the absolute lowest price. High-quality jets can be made in China, and many top brands have already proven it.

All it takes is setting clear standards and managing risks through sampling, testing, and inspections.

Common Questions About Hot Tub Jets

1.Is there a big gap between SPA Jets manufactured in Chinese factories and those produced in Europe and the U.S.?

Under the same standards, the gap is not significant. In fact, Chinese factories have a complete supply chain, lower costs, and high efficiency.

2.How can you tell if a factory is reliable?

See if they have long-term customers (especially European and American brands) and if they can provide test reports.

3.I have a tight budget. Does that mean I must compromise on quality?

Not necessarily. You can adjust parameters within reasonable limits, such as slightly reducing the coating thickness, but you must never use recycled materials or substandard rubber rings.

4.Will samples match the bulk order?

Not always. Without contract terms, factories may make only the samples look good. Always specify in the contract that bulk orders must match approved samples.

5.Can Chinese factories do OEM/ODM?

Many have design capabilities to adjust appearance or improve internal structures, which is why international brands often maintain long-term partnerships.

About Hydrorelax

We have been manufacturing hot tub jets for multiple well-known European and North American brands for over 25 years. We know international standards and how to avoid common quality, packaging, shipping, and customs issues.

We can share real case studies and help you design a complete quality control process, making your sourcing safer and more predictable.