Buying Tempered Shower Glass in Bulk: Safety, Transport, and Supplier Tips

- Share

- Issue Time

- Sep 4,2025

Summary

Tempered glass used in shower accessories has a very low chance of spontaneous breakage—roughly 0.3%, according to studies.

Tempered glass used in shower accessories has a very low chance of spontaneous breakage—roughly 0.3%, according to studies. But even rare events can pose serious safety risks. In a wet, enclosed space like a shower, broken glass can cause cuts, and panic may lead to slips and falls, resulting in worse injuries.

That's why commercial buyers shouldn't overlook this risk, even if it's small. Choosing higher-quality glass from the start and understanding how to prevent breakage are essential for product safety and customer trust.

Why Does Tempered Glass Break on Its Own?

Tempered glass is made by heating it to a high temperature, then cooling it rapidly. This process, called quenching, makes the glass stronger and more heat-resistant. But it also leaves internal stresses.

If there are tiny flaws in the glass,like air bubbles, dust, small scratches, or chips,they can be trouble later. All it takes is the right moment, and the glass might suddenly break on its own. One common cause is a quick change in temperature. For example, if part of the glass is hot and cold water splashes on it, the sudden difference can create stress and make it crack.

In short, tempered glass is strong but sensitive. Breakage doesn't always mean poor quality—it often comes from internal stress points reacting to external forces.

How to Reduce the Risk of Spontaneous Glass Breakage

If you're buying in large quantities and want to avoid this kind of risk, the key is simple: pay attention to how the glass is made and what safety steps are taken afterward.

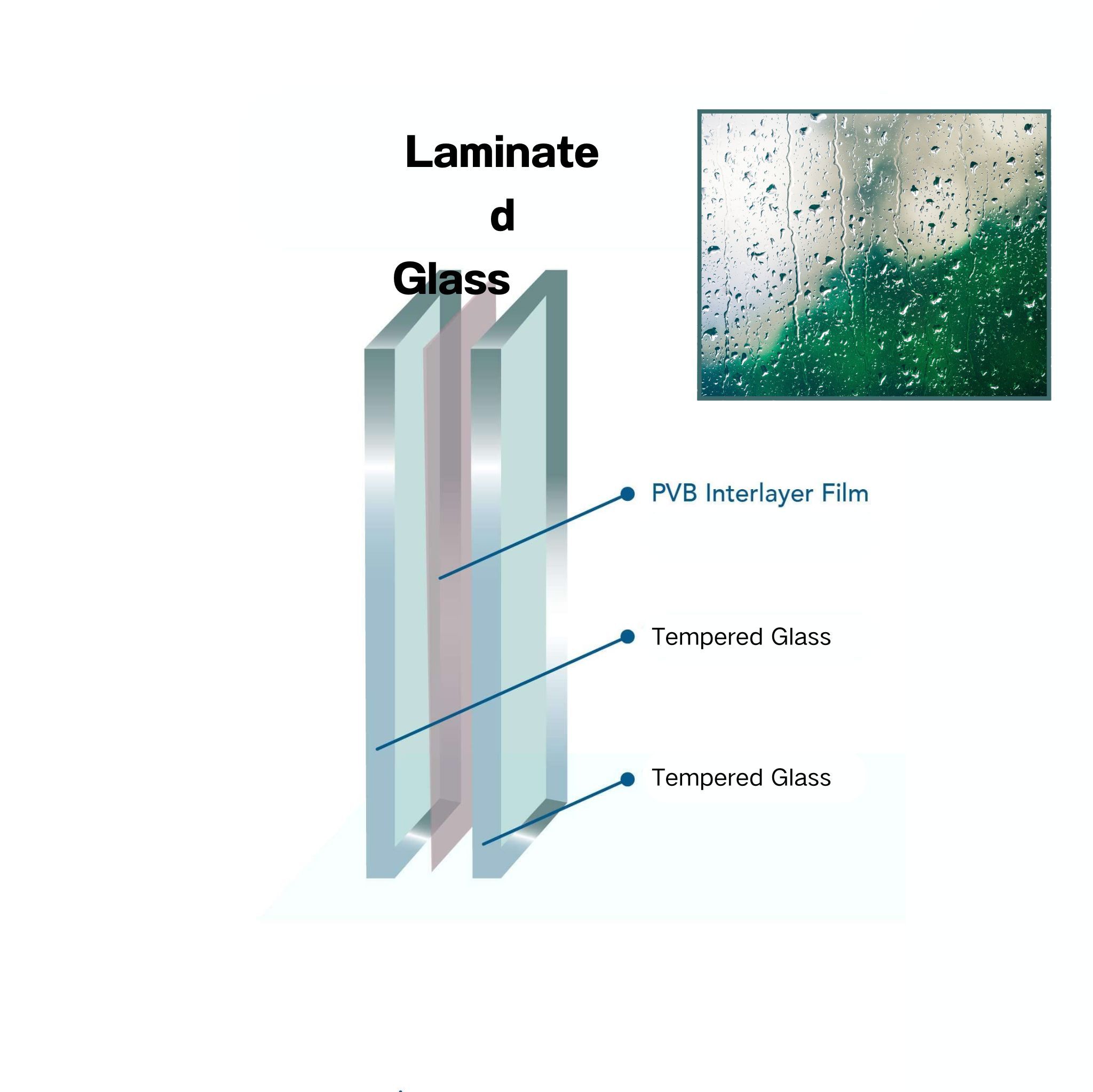

Laminated Glass

Most shower enclosures today use tempered glass because it's strong, heat-resistant, and safer, it breaks into small, dull pieces instead of sharp ones. But even tempered glass can sometimes shatter on its own. To lower that chance, you can choose laminated tempered glass instead.

Think of laminated glass as a sandwich structure: two sheets of tempered glass with a thin plastic layer in the middle. This layer, called PVB, is a tough, flexible material that plays a crucial role in safety.

If the glass breaks, the shards stay stuck to the film instead of scattering. This greatly lowers the chance of injury. In many cases, the glass can still hold its shape and remain usable for a short time.

So, if you're supplying high-end shower fittings or working with clients who prioritize safety, laminated glass is the smart choice. Put simply: even when it breaks, it holds,this is the biggest advantage of laminated glass.

shower tempered glass

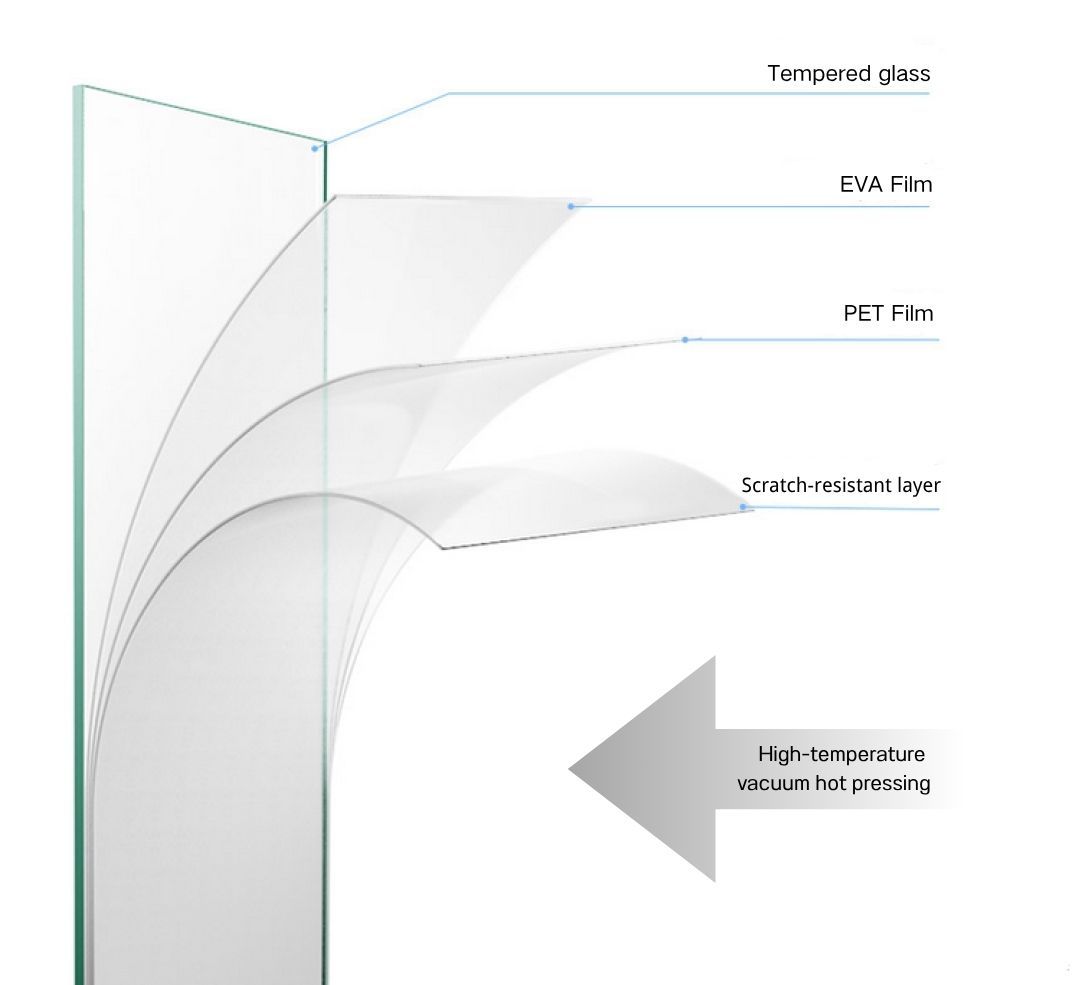

Safety film is another good way to help prevent injuries if the glass breaks on its own. It doesn't change the glass itself. Instead, a clear protective layer is added on top, much like a screen protector on a phone, but made especially for safety purposes.

Once the film is applied, even if the glass breaks, it won't fall apart or fly everywhere. The pieces stick to the film and just crack in place, instead of breaking off like sharp shards.

Adding safety film is a common way to make glass safer. Compared to laminated glass, it's a more budget-friendly option that still offers good protection. That's why it's often used in mid-range projects where safety matters but the budget is tight.

It's a favorite choice for homes with kids or older adults, and for mid-range houses or hotels where builders want to make things safer without spending too much.

How Should Commercial Buyers Choose?

Your choice should depend on brand positioning, project level, and target users:

High-end projects: Laminated tempered glass is ideal. It offers the highest safety with minimal long-term maintenance.

Mid-range projects: Tempered glass with safety film is cost-effective and meets most family safety needs.

Entry-level projects: Use standard tempered glass with strict quality control, proper packaging, and careful installation to reduce stress damage and keep breakage risk low.

How to Safely Transport Shower Glass in Bulk When shipping large quantities of shower glass over long distances, the biggest concern is whether the glass can arrive safely. Though tempered glass is stronger than regular glass, it's still fragile. Uneven pressure or strong vibrations during transit can cause cracks or even breakage.

So how do manufacturers handle this challenge?

Today, most glass factories use standardized reinforced packaging—but thicker cartons alone aren't enough. A proper transport solution usually includes the following:

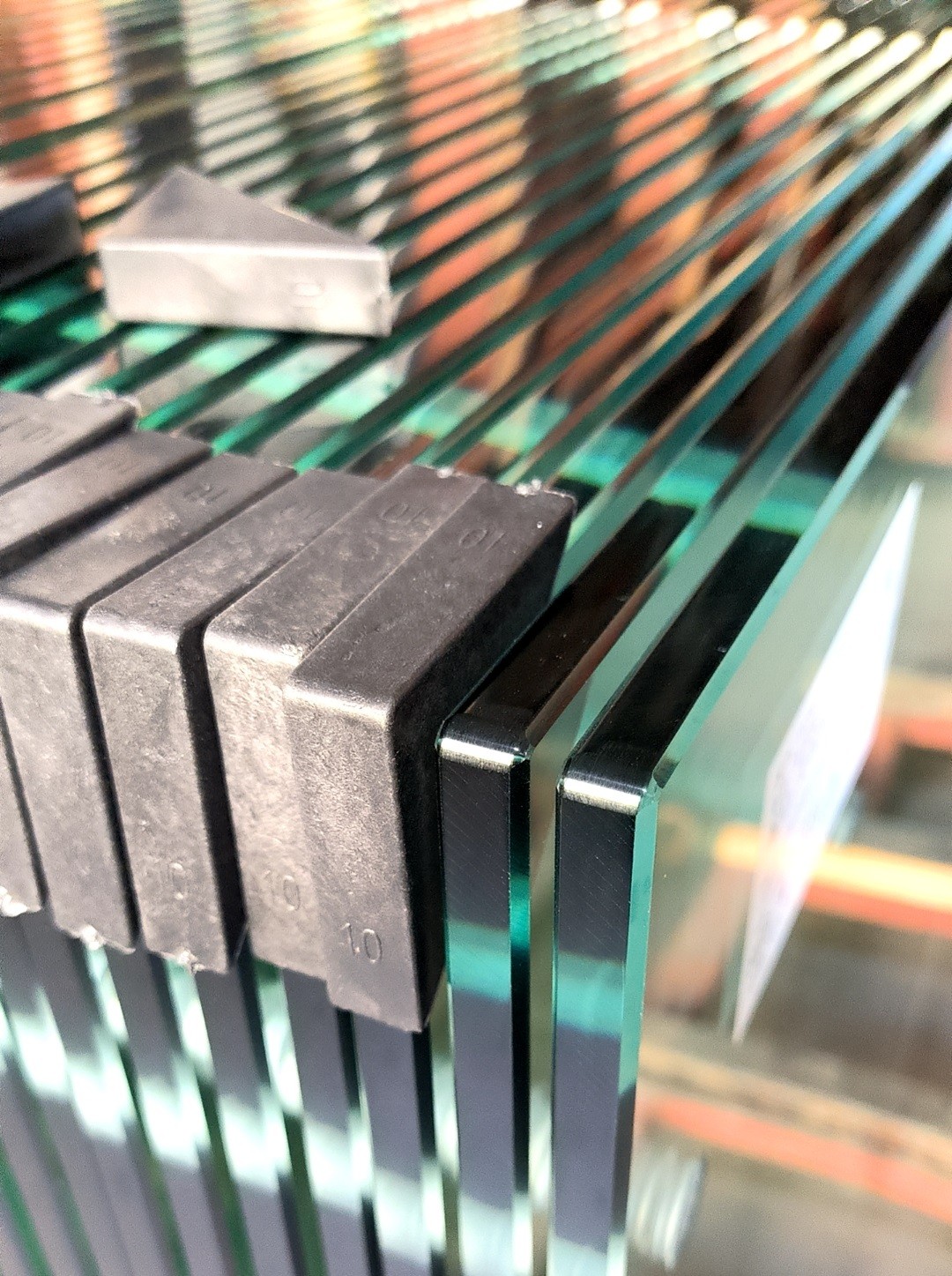

Special Rack Packaging

Glass should always be moved standing up, not lying flat. It needs to be placed on A-frame or T-frame racks, which hold it upright and in line with how the vehicle moves. This helps reduce pressure and shaking from bumps on the road.

Foam sheets, plastic film, or other cushioning materials are placed between each glass panel to prevent scratching, friction, or impact during transit.

Corner Protection

Corners are the weakest points, especially on larger panels. They're prone to chipping or cracking during loading and unloading. Protective corner pads should be applied before shipping to absorb shock.

Clear Labels and Proper Loading

Each package should be clearly marked with 'Fragile,' 'Handle with care,' and 'Do not tip' labels. Glass specs—such as size, thickness, and quantity—should also be marked for easy inspection upon delivery.

When loading glass, it's important to do it the right way—keep it standing upright, secure it tightly, and stack it evenly. If you can, use trucks made for carrying glass, and cover everything with waterproof material to protect it from moisture.

What Can Hydrorelax Offer You?

Now that you know more about shower glass safety and transport, you'll see that international sourcing isn't as complicated as it seems. In China, the production and export of shower glass are well-established. With the right, experienced supplier, the entire sourcing and logistics process can be smooth and reliable.

Hydrorelax is a trusted supplier of shower accessories with 24 years of export experience. We specialize in one-stop solutions and take quality seriously—each glass panel goes through four rounds of inspection to meet export standards.

Here's What We Offer:

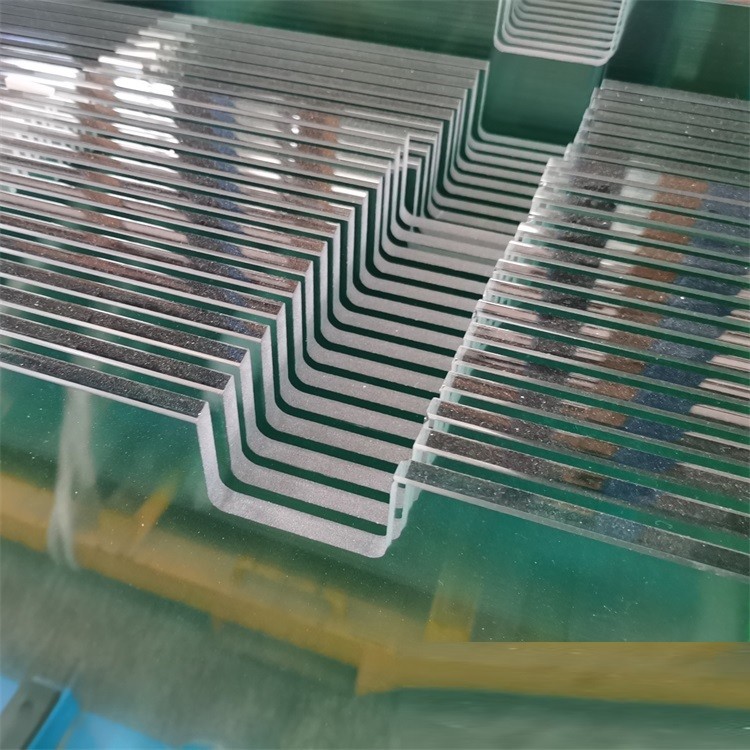

1.Custom production based on your drawings or samples: cutting, drilling, edge polishing, printing, and coating

2.Precision cutting and edging using fully automated equipment

3.Secure wooden crate packaging, with photos taken before shipment

4.Full range of accessories: hinges, seals, rollers, handles, and more

5.Various glass types: low-iron glass, curved glass, frosted, safety-film glass

6.Small batch samples + mass production supported

7.OEM/ODM services with private label shipping

8.Priority production scheduling for long-term partners

Frequently Asked Questions (Q&A)

What types of shower enclosures is your glass suitable for?

Our glass can be used for all common styles,fixed panels, sliding doors, swing doors (inward or outward), and diamond-shaped enclosures. Custom sizes are available.

How do you ensure the glass won't break during transit?

All glass panels undergo edge safety treatment, random breakage testing, and tempering stress checks. For transport, we use reinforced wooden crates and multi-layer cushioning—ideal for long-distance export.

What's your minimum order quantity? Can I mix different products?

Small trial orders are welcome. Glass and hardware accessories can be shipped together to save on shipping costs.

Which countries do you export to most? What certifications can you provide?

We export mainly to Europe, North America, Australia, and the Middle East. CE and other relevant certifications can be provided.

What happens if there's a problem? What after-sales support do you offer?

We offer a 1-year warranty. In case of any issues, we support reshipment or returns through friendly negotiation. Remote video inspections before delivery are available so you can see the product condition clearly.

Can you also supply shower hardware accessories?

Absolutely. We offer a full set of shower hardware—hinges, handles, rollers, seals, and more. Everything can be packed and shipped together to streamline your sourcing and reduce costs.

Looking for a reliable shower glass supplier? Let's talk.

We're more than just a shower glass factory, we're your full-process partner from design, customization, production, and accessory matching to final packaging and delivery.

Contact us today for samples and the latest pricing.

Support Any Customization

Support Any Customization

Support Any Customization