Factory-Made Shower Room Pulleys: A Practical Guide to Solving Real-World Issues

- Share

- Issue Time

- Jun 3,2025

Summary

Most shower room rollers (also called shower pulleys) don't differ much in terms of structure. They're made up of just a few basic components

Most shower room rollers (also called shower pulleys) don't differ much in terms of structure. They're made up of just a few basic components, but because they all look quite similar, many people get confused when choosing or replacing them.

So today, let's quickly identify the differences. You'll be surprised by how detailed this guide gets!

The Structure of a Shower Roller

If we break down the roller, you'll see three parts (including screws): starting from the left, the first part is the main roller body, followed by a cover, screws, and then the sliding cover on the far right.

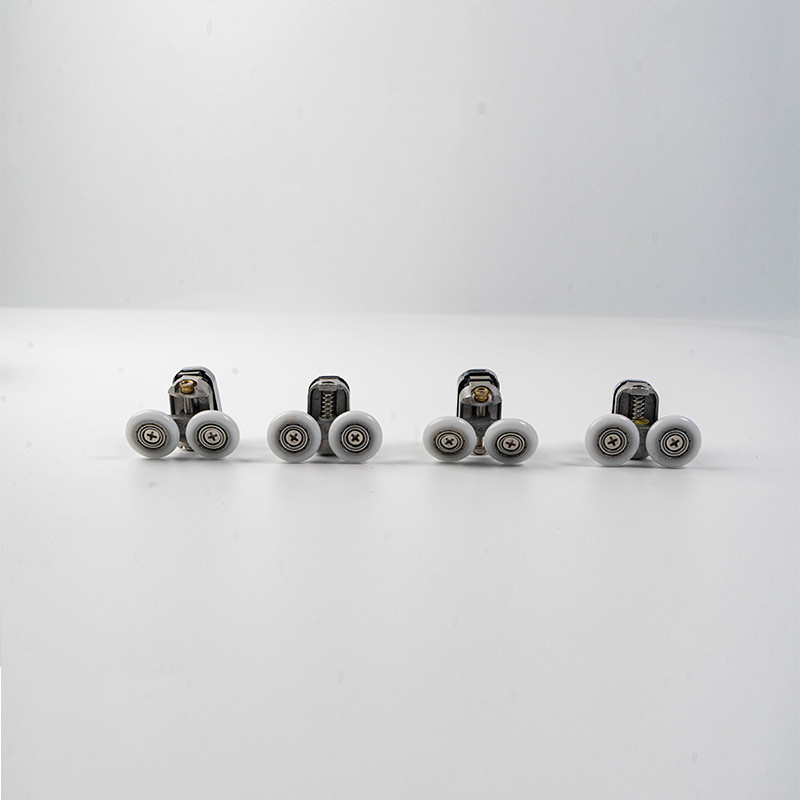

Of course, just breaking them apart isn't enough. When you're actually using them, you'll notice that rollers come in two types: upper rollers and lower rollers. But how do you tell them apart?

It's simple! Look for a raised button spring—that's the lower roller. The height of the button spring can be adjusted automatically with the upper roller. The upper roller, on the other hand, doesn't have a button spring. Instead, it has a stainless steel adjustment screw, which you can use to adjust the height of the glass by either tightening or loosening it.

Additionally, I should point out that the rollers shown above are typically used for sliding shower rooms. The rollers below, however, are designed for corner shower rooms.

Types of Shower Room Rollers

Now that we've identified the structure of the rollers, let's take a look at how we can further categorize them based on different factors to better understand their roles:

1. By Installation Position:

Upper Roller: Installed at the top of the shower door, mainly responsible for bearing the weight.

Lower Roller: Installed at the bottom of the shower door, primarily responsible for guiding the movement.

2. By Number of Rollers:

Single Roller: Typically used for lighter shower doors or lower rollers.

Double Roller: Generally used for heavier, larger shower doors or upper rollers.

Key Parameters of Shower Room Rollers

Glad you've made it to the most important part! Here, you'll quickly learn which dimensions you need to check when evaluating a roller.

1.Installation Thickness:

This refers to the thickness of the glass being installed, typically ranging from 4-6mm or 4-8mm.

2.Wheel Diameter:

The wheel diameter is the outer diameter of the roller, usually measured in millimeters. Common diameters include:

23mm, 25mm, 27mm, and so on.

Larger wheel diameters typically offer stronger weight-bearing capacity, making them suitable for heavier glass doors, while smaller diameters are ideal for lightweight doors, commonly found in smaller or more compact showers.

3.Wheel Thickness:

The actual thickness of the roller wheel, which, together with the wheel diameter, affects the stability and weight capacity of the roller. In general, thicker wheels tend to be more durable and better at supporting heavier loads.

4.Wheel Center Distance:

This is the distance between the centers of the two wheels, affecting how the roller fits with the track. It directly influences the stability and smoothness of the sliding movement during installation. A common center distance is 32mm.

5.Glass Installation Hole Diameter:

When installing a roller, a hole needs to be drilled in the glass door to secure the roller. The hole diameter refers to the size of this hole. It's important that the hole diameter matches the inner diameter of the roller.

6.Distance from Hole Center to Glass Edge:

This refers to the distance from the center of the installation hole to the edge of the glass. Different roller and glass door designs may have varying hole spacing requirements.

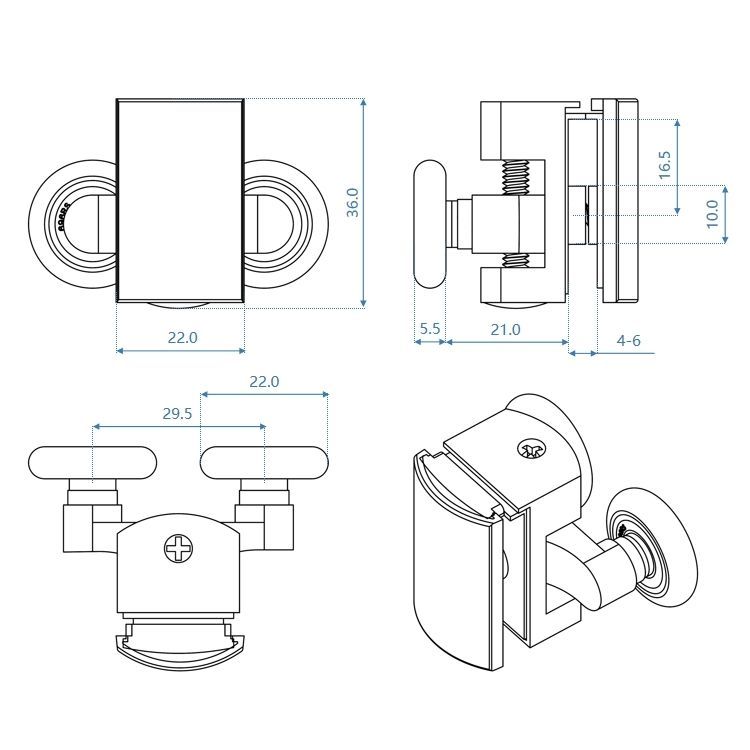

For example, as shown in the image: wheel center distance: 29.5mm, wheel diameter: 22mm, wheel thickness: 5.5mm, installation thickness: 4-6mm, glass installation hole diameter: 10.0mm, and distance from hole center to glass edge: 16.5mm.

Materials of Shower Room Rollers

Here's an overview of the common materials used in different parts of the roller structure:

1. The Wheel (the part that contacts the track):

PA (Polyamide): This is a popular material for the wheels due to its strong abrasion resistance, smooth sliding capability, and reasonable cost.

2. The Roller Bracket and Bearing Part:

Stainless Steel: Often used for the roller bracket and external frame, stainless steel is highly corrosion-resistant and durable, making it ideal for use in damp environments.

Plastic: Budget-friendly roller brackets are often made from plastic, especially in products where cost control is a priority.

3. Internal Components of the Roller (such as bearings and sliding tracks):

Plastic: The sliding track and some bearings inside the roller may be made from plastic, which effectively reduces friction and noise, ensuring a smooth sliding experience.

Steel or Stainless Steel Bearings: Higher-end rollers often use steel or stainless steel bearings to enhance durability and load-bearing capacity.

Shower Room Pulley Q&A

1.Why do rollers rust?

Rollers typically rust due to poor material quality or prolonged exposure to a humid environment. Choosing rollers made of stainless steel or those with anti-corrosion treatments can effectively prevent rust.

2.What should I do if the roller can't support enough weight?

If the roller is not bearing enough weight, it’s recommended to opt for rollers with a larger wheel diameter or use materials with stronger load-bearing capacity to ensure it can support the weight of the door.

3.How can I solve excessive noise from the rollers?

Excessive noise from the rollers can negatively affect the user experience. You should check if the noise is due to damaged or worn-out bearings. If that's the case, replace the roller promptly or apply lubricant to reduce the noise.

4.What is the typical lifespan of a roller?

The lifespan of a roller is generally dependent on factors like usage frequency, material quality, and bearing condition. High-quality rollers can last anywhere between 5 to 10 years. In high-usage or high-humidity environments, they might need to be replaced sooner. Typically, stainless steel rollers can last over 8 years.

How to Evaluate Suppliers and Ensure Product Quality

As a brand owner or wholesaler, choosing a reliable roller supplier is crucial. Here are some key factors to consider when evaluating a supplier:

1. Product Quality Assurance

The supplier should provide detailed quality inspection reports to ensure the rollers have undergone rigorous testing and meet standards for durability, load-bearing capacity, and smooth sliding performance. A reputable supplier typically conducts various performance tests on the rollers, including sliding tests, load tests, and noise tests.

2. Material Selection and Customization Capabilities

A high-quality roller supplier will offer a variety of materials based on market demand and be able to provide customization services to meet different customer needs. If a customer has specific requirements, the supplier should be able to offer professional design solutions and technical support tailored to those needs.

3. Production Processes and Precision

A top-tier roller supplier will use advanced manufacturing processes to ensure each roller is produced with high precision, minimizing the risk of issues like jams or unstable quality due to poor production techniques.

4. After-Sales Service and Technical Support

In addition to offering high-quality products, an excellent roller supplier should provide prompt after-sales service and technical support to help customers address any issues encountered during use. Professional technical support can also assist customers in understanding proper product usage and installation methods, helping to avoid roller failure due to installation errors.

Hydrorelax: Your Professional Shower Room Pulley Solution Supplier

As a manufacturer with 24 years of experience, Hydrorelax is committed to providing high-quality shower room accessories, including shower room pulleys, to customers worldwide.

We employ advanced manufacturing processes and a strict quality control system to ensure that each pulley meets high standards.

If you have any questions or need further technical support regarding shower room pulleys, feel free to contact us anytime.

Price in Set, 23pcs per Set

Wheel diameter:20-26mm

Diameter: 19-26mm

Material: PA+ABS

Diameter: 19-26mm

Material: Zinc alloy+ABS