How to Choose the Best Shower Door Hinges 2025

- Share

- Issue Time

- May 28,2025

Summary

Shower door hinges can support glass doors weighing over 30kg (with common glass thicknesses between 8-12mm), and allow them to open and close frequently without any damage.

Shower door hinges can support glass doors weighing over 30kg (with common glass thicknesses between 8-12mm), and allow them to open and close frequently without any damage. How do they manage this? What makes such a small and simple component play such an important role? With so many types of hinges on the market that look similar, what's the difference between them? Should you choose 304 stainless steel or zinc alloy?

We've put together a complete guide on shower door hinges. Whether you're a bathroom wholesaler, shower door manufacturer, or a homeowner, we hope this guide provides valuable insights for you.

What is the Basic Structure of a Shower Door Hinge?

The primary function of a shower door hinge is to connect two pieces of glass or a glass door to the wall, allowing the door to rotate open. Here are the most common hinge types available today:

1. Spring Hinge

The spring hinge uses an internal spring to control the return angle, automatically closing the door. It's mainly used for one-way opening doors.

Advantages: Auto-return feature, prevents accidental openings.

Disadvantages: The spring can wear out over time, leading to poor return action after long-term use.

2. Positioning Hinge

This hinge offers multiple angle stops, such as 0°, 90°, and 135°, making it suitable for folding doors or special opening angles.

Advantages: Multiple angle stops, versatile for different needs.

Disadvantages: More complex design, requiring higher precision in manufacturing.

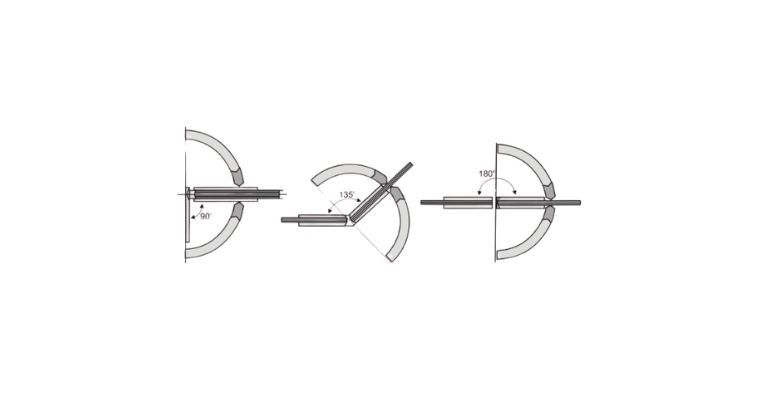

90° Hinge: The glass door opens vertically to 90°, the most common type, suitable for square shower enclosures.

135° Hinge: The door opens at a 135° angle, often used for diamond-shaped or polygonal structures.

180° Hinge: The door can open in both directions or fully open against the wall, commonly used in double-door or corner shower enclosures.

Key Reminders:

1. Door opening direction limitations:

You must determine in advance whether the door will open inward, outward, or in both directions to select the appropriate hinge structure.

2. Practical advice:

Provide construction drawings and door frame details to the factory or supplier to help confirm the correct opening angle and hinge style. If unsure, choose a model with a larger angle range and positioning support.

What Are the Different Types and Installation Methods for Hinges?

The choice of hinge installation method can vary greatly depending on the project requirements. Here are the common types and their applications:

| Hinge Type | Application Location | Features |

| Glass-to-Glass Hinge | Between two pieces of glass,frameless shower door | Used to connect the fixed panel and the movable door. |

| Glass-to-Wall Hinge | Between glass and wall | Typically installed on a frame wall or tiled surface. |

| Top-Mounted Hinge | Suspended from the top track | Often used with a roller system. |

Inward/Outward Hinge | Controls door opening direction | Ensures the correct opening angle and prevents collisions. |

Some systems come as complete "kits" (e.g., double hinges + fixed support rods + anti-slip seats). When purchasing, it's recommended to prioritize a full set design to avoid compatibility issues

Hinge Material Selection

The quality of a hinge is primarily determined by its material and surface treatment process.

Recommended materials for the hinge body:

Stainless Steel (SS304):

Corrosion-resistant and acid/alkali-resistant, making it the most reliable choice for high-humidity environments.

Aluminum Alloy:

Lightweight, typically used for mid to low-end markets.

Special Reminder: The best choice is a brass or stainless steel glass door hinge. These materials are the most reliable, especially for heavy tempered glass doors weighing 30-40kg. Zinc alloy or aluminum alloy hinges may break or corrode over time, so be sure to consider this carefully.

Surface Treatment Comparison

| Process Type | Applicable Materials | Advantages | Risk Points |

| Mirror Polishing | Stainless Steel, Brass | High gloss, premium visual appeal | Prone to fingerprints, scratches visible |

| Brushed Finish | Stainless Steel, Aluminum Alloy | Fine texture, wear and scratch resistant | Uneven lines may affect aesthetics |

| Electroplating | Zinc Alloy, Brass (some Aluminum) | Multiple color options, strong corrosion resistance | Poor-quality plating can peel off |

Spray Coating (Black/Gray, etc.) | Aluminum Alloy, Zinc Alloy, Stainless Steel (after surface pre-treatment) | Modern style, popular finish | Sensitive to strong acid cleaners, paint may peel off |

Note:

Standard decorative electroplating is mainly used for zinc alloys and brass. Stainless steel can achieve decorative colors through advanced processes like PVD, but this comes at a higher cost.

Advice:

When inspecting samples, pay attention to whether there are bright spots, coating particles, or waves under natural and artificial light—these could indicate issues with the manufacturing quality.

The Key to Hinge Weight Capacity

By now, you should have a basic understanding of shower door hinges. So, how can such a small component support a glass door weighing tens of kilograms?

The answer lies in: Structural Design + Material Strength + Manufacturing Precision

High-quality shower door hinges feature a multi-axis design with a well-distributed lever arm, ensuring the weight of the door is evenly spread across the wall or fixed glass.

Additionally, materials like 304 stainless steel, brass, and zinc alloy die-castings offer high bending strength, meaning the load-bearing parts won't fatigue or break under repeated stress. This is what enables them to support such heavy weights.

Common Issues & Tips About Hinge

Issue 1: Door Sags, "Catches" After 6 Months

Cause: Wear on the hinge bearings or washers, or improper angle calibration during installation.

Tip: Choose a product from a brand with a well-designed structure; always test door closure after installation.

Issue 2: Unusual Noise When Opening

Cause: Misalignment of the pivot or spring, or insufficient lubrication.

Tip: Opt for high-precision hinges; check smooth movement before installation.

Issue 3: Glass Shatters, Cracks Found at the Hinge Clamping Area

Cause: Over-tightened clamping structure, or missing/wrongly positioned washers.

Tip: Use flexible anti-explosion washers and leave proper space during installation for movement.

Key Points to Confirm Before Purchasing

As a buyer or project manager, even if you're not responsible for production, it's crucial to communicate these key parameters with the factory:

1.Glass Thickness (common: 8mm/10mm/12mm, design varies)

2.Hinge Size & Opening Angle (matches door frame size, any auto-return needed)

3.Weight Capacity (20kg/25kg/30kg per hinge? Data required)

4.Structural Diagram or Installation Video (for efficient installation)

5.Packaging & Shipping Protection (to prevent damage or scratches)

Hydrorelax Shower Door Hinges

Hydrorelax offers a variety of shower door hinges, backed by 24 years of experience in manufacturing shower accessories. If you'd like more detailed information on product selection or project customization, feel free to contact us anytime. We're here to leverage our 24 years of expertise to help you make the best professional decision.

Glass thickness: 4-8mm

Opening angle: 180 degree

Rose gold Zn Alloy

Glass thickness: 4-8mm

Opening angle: 180 degree