How to Choose the Right Spa Air Control for Your Spa System

- Share

- Issue Time

- Aug 6,2025

Summary

What Is a Spa Air Control?A spa air control valve is a device used to regulate the amount of air drawn into the jets.

What Is a Spa Air Control?

1.Function:

A spa air control valve is a device used to regulate the amount of air drawn into the jets.

2.Working Principle:

When water flows through the narrow passage inside a jet, it accelerates and creates a low-pressure area around the jet. This pressure difference draws air in through the air control valve, mixing it with the water to form fine bubbles — a phenomenon known as the Venturi Effect.

3.Power Requirement:

In spa systems, the air control valve itself contains no motorized components. It operates entirely through mechanical adjustment and does not require any electrical power.

4.Operation Mechanism:

By turning a knob or switch, users can increase or decrease the amount of air mixed into the water flow. This effectively controls the intensity and density of the bubbles, allowing for different levels of massage pressure.

5.Optional or Required:

Air control valves are not mandatory in all spa systems. If a user wishes to manually adjust the strength of the bubbles, an air valve is necessary. However, if the spa is designed with a fixed air-to-water ratio (pre-set jets with no airflow adjustment), the system may not require an air control valve.

Key Specifications of Spa Air Control Valves

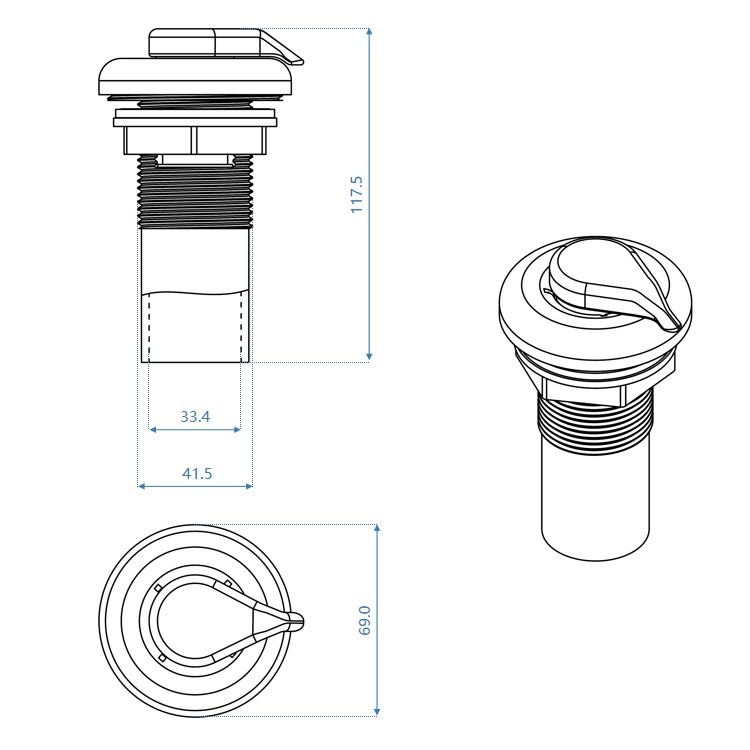

Dimensions

1.Cover Diameter:

The part of the valve exposed on the spa surface, which is visible and operated by the user. It affects the overall appearance and tactile feel during adjustment.

2.Installation Diameter:

The diameter between the cover and the valve body that fits through the spa panel. This determines whether the valve is compatible with the existing panel cutout.

3.Connection Diameter:

The diameter of the bottom air inlet where the valve connects to the air tubing. It must match the tubing size to ensure airtight sealing and adequate airflow.

4.Body Height:

The vertical length of the PVC valve body below the panel surface. This affects the space required for installation and the degree to which the valve is hidden.

Thread

Threaded connection is a critical factor in determining whether the air control valve is compatible with pipelines, jets, or other fittings. It is essential to clarify whether the thread standard is BSP (British Standard Pipe) or NPT (National Pipe Taper). Mismatched threads may lead to installation failure or air leakage.

Flow Rate

The valve's airflow capacity reflects the maximum amount of air it can draw into the water stream, which directly affects bubble production. The larger the internal passage and the lower the resistance, the stronger the airflow. A larger port diameter allows more air to enter per unit of time. Typical units are L/min or SCFM.

If the jet is designed to draw a large volume of air but the air valve is too small, system performance will be compromised. Likewise, if the air pump is too powerful for a low-flow valve, issues like backpressure or weak bubbling may occur.

Material

Body Material

The main valve body is commonly made of PVC, while a few models are made of brass.

PVC is lightweight, corrosion-resistant, and ideal for home spas or cost-sensitive systems.

Brass is durable and robust, making it suitable for high-end installations and commercial environments with frequent usage.

Cover Material

Valve covers are typically made from ABS, stainless steel, or brass.

ABS offers high cost-efficiency and is easy to mold—suitable for most mid-range products.

Stainless steel is corrosion-resistant and long-lasting, often used in high-end or public spa settings.

All of these materials are heat-resistant and aging-resistant, making them suitable for long-term use in hot and humid spa environments.

Surface Finish

The surface treatment of the knob or cover affects the visual appeal and tactile feel. Common finishes include chrome plating, brushed nickel, spray painting, brushed texture, and matte finish. Custom finishes are available upon request.

A high-quality surface not only enhances aesthetics but also offers better scratch resistance, anti-fingerprint properties, and overall durability.

Comparison: 3/4" vs 1" Spa Air Control

3/4" Air Valve | 1" Air Valve | |

| Airflow Rate | Medium (Approx. 40–70 L/min) | High (Up to 80–120+ L/min) |

Jet Coverage | 1–2 jets | 2–4 jets or more |

Recommended Pump Power | For 400–700W air pumps | For ≥700W or central systems |

Installation Footprint | Compact size, easier to install | Larger size, needs more space |

| Bubble Performance | Softer bubbles, suitable for gentle massage; weakens when overloaded | Stronger, fuller bubbles; stable even with multiple jets |

| Application Scenario | Home spas, compact tubs | Commercial spas, hotel or multi-jet systems |

| Cost Level | Lower cost, budget-friendly | Higher cost, suitable for premium systems |

Compatibility Between Air Controls and Jets

In a spa system, the "compatibility" between an air control valve and a jet goes far beyond just physical connection. It also involves airflow matching, installation stability, and material compatibility—all of which directly impact the efficiency of the bubble system and the end-user experience.

B2B buyers should pay close attention to the following key compatibility factors:

1.Connection standard:

Thread types (e.g., BSP or NPT) and diameters (e.g., 1/2", 3/4") must match. A mismatch may cause air leakage or assembly failure.

2.Airflow capacity:

The valve's maximum air throughput should align with the jet's designed capacity to avoid weak bubbling or system overload.

3.Installation method:

Whether the parts are designed for recessed or surface mounting affects whether they can be properly positioned and secured in a given system layout.

4.Material and environment:

ABS, stainless steel, and other materials behave differently under heat and humidity. Long-term durability and resistance to corrosion must be considered.

5.Service life and maintenance:

Consider ease of cleaning, frequency of disassembly, and stability of connection over time.

Installation and Maintenance Tips for Spa Air Control Valves

Installation Tips

1.Placement:

Install the valve close to the blower to reduce air resistance.

2.Sealing:

Use Teflon tape or thread sealant to prevent air leakage.

3.Tightening:

Avoid over-tightening the threads to prevent damage to the valve structure.

4.Orientation:

Ensure the valve knob or handle is positioned for easy access and operation.

Maintenance Guide

1.Regular Inspection:

Check monthly for cracks, loose threads, or debris buildup.

2.Annual Cleaning:

Clean the valve annually to remove scale and impurities.

3.Frost Protection:

Drain water from the valve to prevent freezing damage in cold weather.

4.UV Protection:

For outdoor use, shield the valve from sunlight or use UV-resistant materials.

5.Lubrication:

Apply a silicone-based lubricant to moving parts once a year to maintain smooth operation.

Troubleshooting

1.Weak Jet Output:

Check for blockages or worn-out seals in the air valve.

2.Air Leaks:

Tighten connections or replace O-rings as needed.

Hydrorelax Air Control Solutions

When selecting spa bathtub components, the compatibility between air control valves and jets is one of the most common concerns for engineering purchasers and OEM clients.

Hydrorelax offers a full range of spa air control valves specifically designed for different bathtub systems. Covering mainstream sizes such as 3/4" and 1", our valves come in various structures and are fully compatible with a wide array of jets and air pipelines. They are widely used in residential tubs, commercial spa projects, and custom-engineered systems. Each valve is engineered to ensure precise alignment and leak-free operation with the jets, significantly reducing installation complexity and after-sales issues.

Beyond standard products, we also provide fully customized air control valve solutions based on client drawings, system airflow requirements, and connection specifications—ensuring both functional efficiency and aesthetic integration for special projects.

We support bulk orders, low-volume prototyping, and structural optimization to help you quickly implement a highly compatible and reliable spa solution.

If you are looking for a highly compatible and cost-effective one-stop solution, we offer sample testing and OEM customization services. Feel free to contact us anytime for detailed specifications and wholesale pricing!

For more insights on spa parts, check out our blog collection right here.