Shower Accessories Factory Wholesale Guide: Choosing the Best Surface Treatment

- Share

- Issue Time

- Jul 31,2025

Summary

How much do you really know about surface finishes for shower accessories?For many people, this question may not cause much concern.

How much do you really know about surface finishes for shower accessories?

For many people, this question may not cause much concern. However, for commercial customers purchasing shower fittings wholesale, ignoring this detail can bring no small amount of risk - in terms of cost, product quality and long-term results.

Take the black finish for example, you can choose between electroplating or baking paint, but what are your selection criteria? Is it clear what the difference between the two is and how it applies?

In this blog, we'll walk you through the most common surface treatments, their features, pros and cons, and when to use them—so you can make smarter, more informed decisions.

Electroplating

Electroplating adds a thin metal layer—like nickel, zinc, or copper—onto the surface to boost corrosion resistance, wear resistance, and shine. It gives shower accessories a sleek, high-end look.

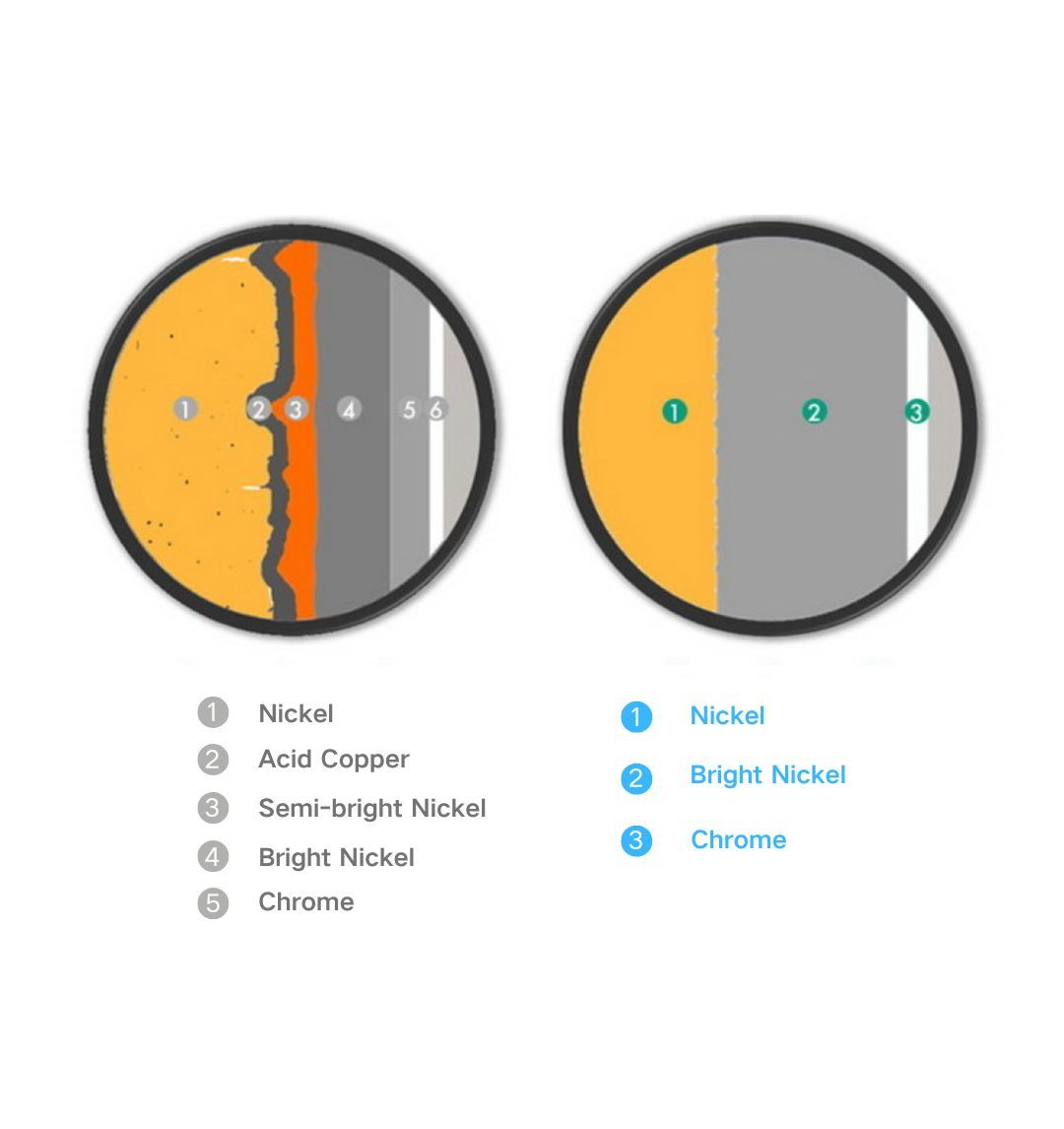

1.Typical 3-layer structure:

Copper base – seals the surface and improves adhesion.

Nickel layer – strong against oxidation and rust.

Chrome finish – stays shiny and stable over time.

The result: a mirror-like surface with a smooth, premium feel. One small downside? It shows fingerprints and water spots easily—but a quick wipe with a cloth brings it right back.

2. Beware of over-plating

More layers don't always mean better quality. Some claim 5–6 layers of plating—but this might just cover up poor materials or bad casting.

A good base and solid plating technique matter more. High-quality copper with minimal impurities is the real key.

Brushed Finish

Unlike glossy plating, brushed finishes offer a soft, matte look. They reduce glare, hide fingerprints, and mask minor flaws.

Electroplating vs. Brushed Finish

1.Key features:

Brushed textures—straight, wavy, or circular—are made by sanding over a nickel layer. This adds visual depth and boosts durability.

A PVD coating is usually added after brushing to protect against rust, oxidation, and smudges.

2. Stainless Steel vs. Copper

Brushed finishes work on both stainless steel and copper.

304 stainless is common in high-end accessories, but it's harder to process—some factories may struggle to achieve a flawless finish.

Copper, on the other hand, is easier to work with and often delivers smoother, more refined results.

Painted Finish

Black shower hardware has become a design favorite in recent years. It's typically done by plating or painting—painted finishes are great for large-scale production due to their lower cost and consistent quality.

1. Why painting works

Multiple paint layers are sprayed on and baked at high heat, forming a strong, even coating. The result: a smooth, solid color that's hard to fade or peel—ideal for sleek black finishes.

2. Paint vs. plating

Black plating is more expensive and technically demanding. That's why many black fixtures use paint instead. Done well, it offers excellent value and fits perfectly with modern, minimalist styles.

Q&A on Shower Accessory Surface Finishes

Q1: How do I choose the right surface finish?

It depends on your product positioning, market needs, and balance between cost and durability.

-Plating suits mid-to-high-end items needing shine and corrosion resistance.

-Brushed finishes work well for matte, understated styles and offer great wear resistance.

-Painting is budget-friendly and ideal for custom colors like black, though less durable over time.

Q2: Which finish lasts the longest?

Plating and brushing are better for long-term use. Plating resists corrosion well, while brushed finishes hold up nicely in humid environments. Painted finishes look modern but may need more maintenance over time.

Q3: How can I tell if the quality is good?

Ask about acid salt spray test results. This test shows how fast a finish corrodes in acidic conditions. Reliable manufacturers usually share this data as proof of product quality.

Hydrorelax Helps You Choose

Surface finish matters—it shapes both the look and long-term performance of your shower hardware. Plating, brushing, and painting all have their strengths. Beyond looks and cost, think about durability and upkeep too.

Need help picking the right finish for your project or budget? We're here for you.

Contact us—we'll help you find the perfect match!