What to Watch Out for When Sourcing Shower Mixing Valves from China?

- Share

- Issue Time

- Sep 24,2025

Summary

A well-made valve ensures steady water temperature, safe use, and fewer service calls; a poor one can mean leaks, unstable temperatures, complaints, and even safety risks.

In bathroom hardware, the mixing valve rarely draws consumer attention, yet for importers, distributors, and contractors, it's often the biggest headache. It's one of the most failure-prone accessories. A well-made valve ensures steady water temperature, safe use, and fewer service calls; a poor one can mean leaks, unstable temperatures, complaints, and even safety risks.

That's why sourcing valves from China is never just about price. While China is a global hub for shower room products, quality, standards, and service vary dramatically between factories.

Common questions buyers face include

1.How can I be sure the valve meets international standards?

2.Why can two brass valves that look alike differ so much in price?

3.If I choose a cheaper option to save costs, could it cause bigger problems down the line?

This blog draws on experience to highlight four key areas you must check when sourcing, and how to avoid the pitfalls.

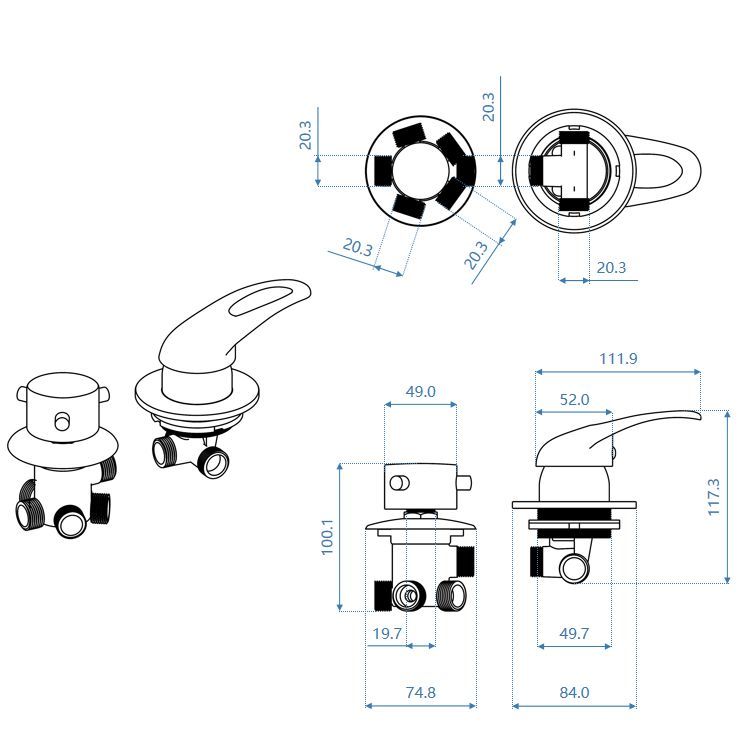

Check the Technical Specs of Shower Valves

Most people think a mixed shower valve is just a brass piece with a cartridge, and that they're all pretty much the same. But in reality, lots of tiny details can make a big difference in how long it lasts and how well it works.

Key parameters to verify include:

Material

Solid brass, stainless steel, or zinc alloy with copper plating? The difference is huge.

Center Distance

150mm is common in Europe, but not every factory guarantees accuracy.

Cartridge Type

Ceramic cartridges are standard, but some can last several times longer than others.

Can it handle your local water pressure?

Surface Finish

Chrome, brushed nickel, matte black, not just about looks, but also corrosion resistance.

Risk Alert

Some factories give vague answers, telling you there won't be any issues, but they won't actually share technical drawings or test reports. Even worse, some try to pass off copper-plated zinc alloy as solid brass. It might look fine at first, but within six months it could start rusting or even break.

TIP

Always request detailed specifications, test data, and plating thickness reports before placing an order. If a supplier can't provide them, it's a clear red flag.

Is Comparing Prices Enough?

Anyone who's sourced from China knows this: two shower accessory suppliers may offer what looks like the same valve, yet one is 30–40% cheaper. Why? The differences usually lie in areas such as:

Brass Grade

Some use Grade 59 or low-lead brass, while others cut costs with recycled brass high in lead, risking durability and even regulatory compliance.

Quality plating passes a 48–96 hour salt spray test ; poor plating may blister within 12 hours.

Cartridge Quality

A good cartridge can last a decade; a poor one may start leaking in months.

Buyer's Note

You can judge brass grade by weight, price, and manufacturer credentials. Even with trusted suppliers, it's wise to check prices regularly, as copper and zinc costs fluctuate and directly affect your margins.

And if you see a 'same material' valve offered at half the market price, please be cautious. The savings upfront may cost far more in returns, service, and brand damage.

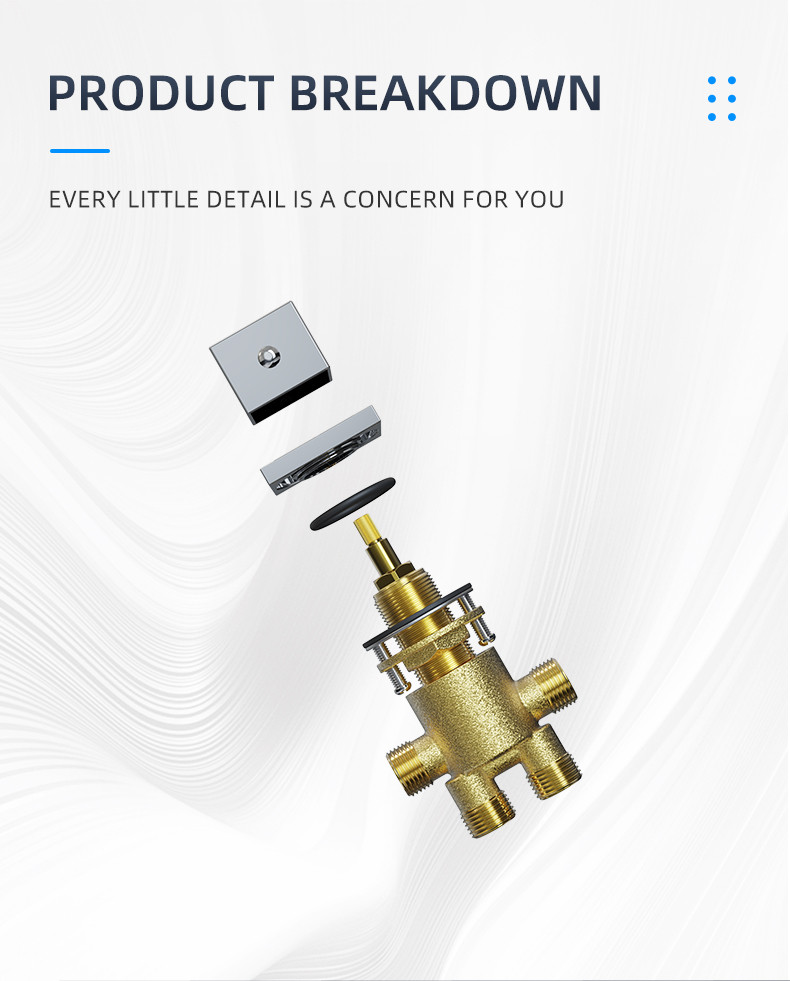

Know the Craft and Standards Behind Shower Valves

Mixing valves are precision accessories with little margin for error. Even a minor flaw in workmanship can cause leaks, cracks, or dangerous temperature swings.

Key areas to check:

Machining Accuracy

Are the threads clean and smooth? Poor threading leads to leaks and may damage fittings during installation.

Cartridge Assembly

Is it positioned correctly? Misalignment throws off the hot/cold water balance.

Plating Quality

Don't judge by shine alone; durability and rust resistance matter more.

Testing Process

Reputable factories run pressure, flow, and even life-cycle tests that simulate years of use.

Unfortunately, some low-cost factories skip these steps, doing only a surface check before shipping.

Recommendation

Ask for test reports,and even request video proof of the testing process.

Do Your Homework Before Committing

A supplier's reliability isn't just about the product; it's also about the stability of their business. Before you commit, take time to verify their background.

Practical steps include:

Check Business Registration

Use Chinese government platforms or third-party services like Qichacha.

Ask for References

Request case studies of exports to your target market.

Factory Audit

Even a single third-party audit can eliminate most risks.

Exhibition Records

Suppliers who regularly attend events like the Canton Fair or international expos usually value long-term partnerships.

Don't rush into an order just because of a nice sample or a cheap quote. In global trade, choosing the wrong partner can be far costlier than paying a bit more upfront.

Shower Valve FAQs

Is it worth visiting the factory in person?

If budget allows, absolutely. Nothing is more convincing than seeing the production line yourself. If not, hire a third-party for a factory audit.

How do I balance price and quality?

Think long-term. A high-quality mixing valve reduces returns, after-sales costs, and protects your brand. Cheap valves may save a little upfront, but often cost far more later.

How big is the difference between materials?

Huge. Solid brass valves are durable and fit mid- to high-end markets; stainless steel offers corrosion resistance; zinc alloy is common in low-cost markets, but usually short-lived and unstable.

Do samples represent mass production quality?

Not always. Samples are often the best the factory can make. In mass production, shortcuts may appear. Always arrange a third-party inspection before shipment.

What's the most overlooked detail before ordering?

Packaging. Many focus only on the valve, forgetting that poor packaging can cause damage during transport. Request double-layer protection or custom cartons for long-distance shipment.

What if the bulk order quality is worse than the sample?

If your contract lacks inspection standards and return terms, you're at a disadvantage. Always define materials, testing standards, delivery terms, and remedies for defects clearly in the contract.

Hydrorelax: Reliable Supplier of High-Quality Shower Valves

Sourcing shower mixing valves from China comes with both opportunities and risks. By checking key specifications, comparing prices wisely, verifying quality standards, and carefully vetting suppliers, you can minimize risks and make procurement safer and more efficient.

At Hydrorelax, we bring over 20 years of experience supplying shower and spa components to customers in Europe and North America. We understand international standards, conduct strict quality testing, and offer customization to meet specific needs.

If you're planning to source shower mixer valve, or looking to strengthen your current supply chain, please feel free to contact us. Making procurement more transparent and reliable is what we strive for every day.