Bulk Buying Shower Hardware: 5 Details You Can Not Miss

- Share

- Issue Time

- Sep 30,2025

Summary

For importers, securing large volumes of reliable, good-quality products on time can make or break your margins and business stability.

In the shower enclosure industry, shower hardware is always in high demand. Shower bars, rollers, mixers, hoses, overhead showers, and fittings, these accessories may look small, but they're essentials for both projects and retail.

For importers, securing large volumes of reliable, good-quality products on time can make or break your margins and business stability.

So, what should you really pay attention to when placing bulk orders? Here are 5 key points to help you cut risks and work smarter with suppliers.

Be Clear on Specs and Materials

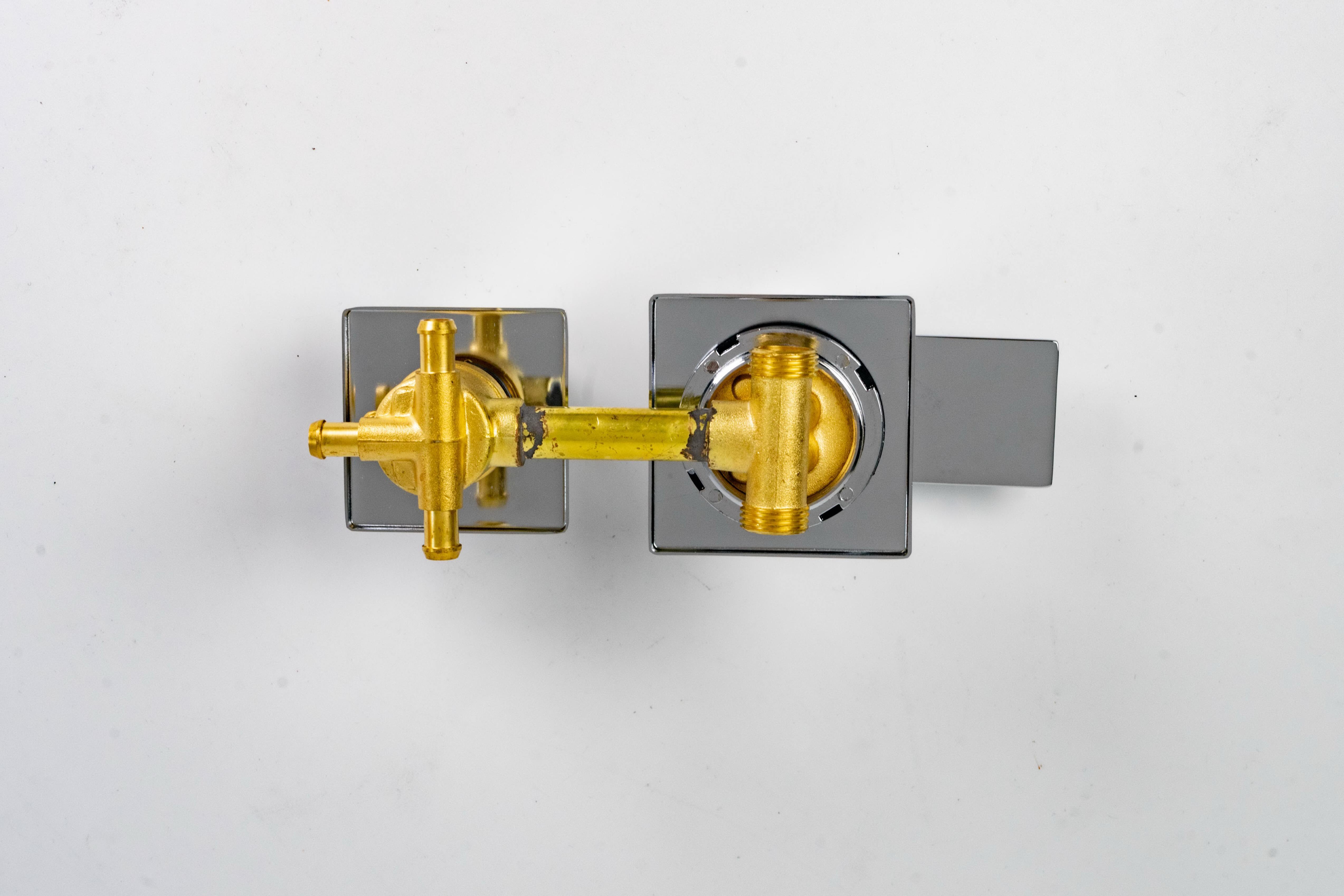

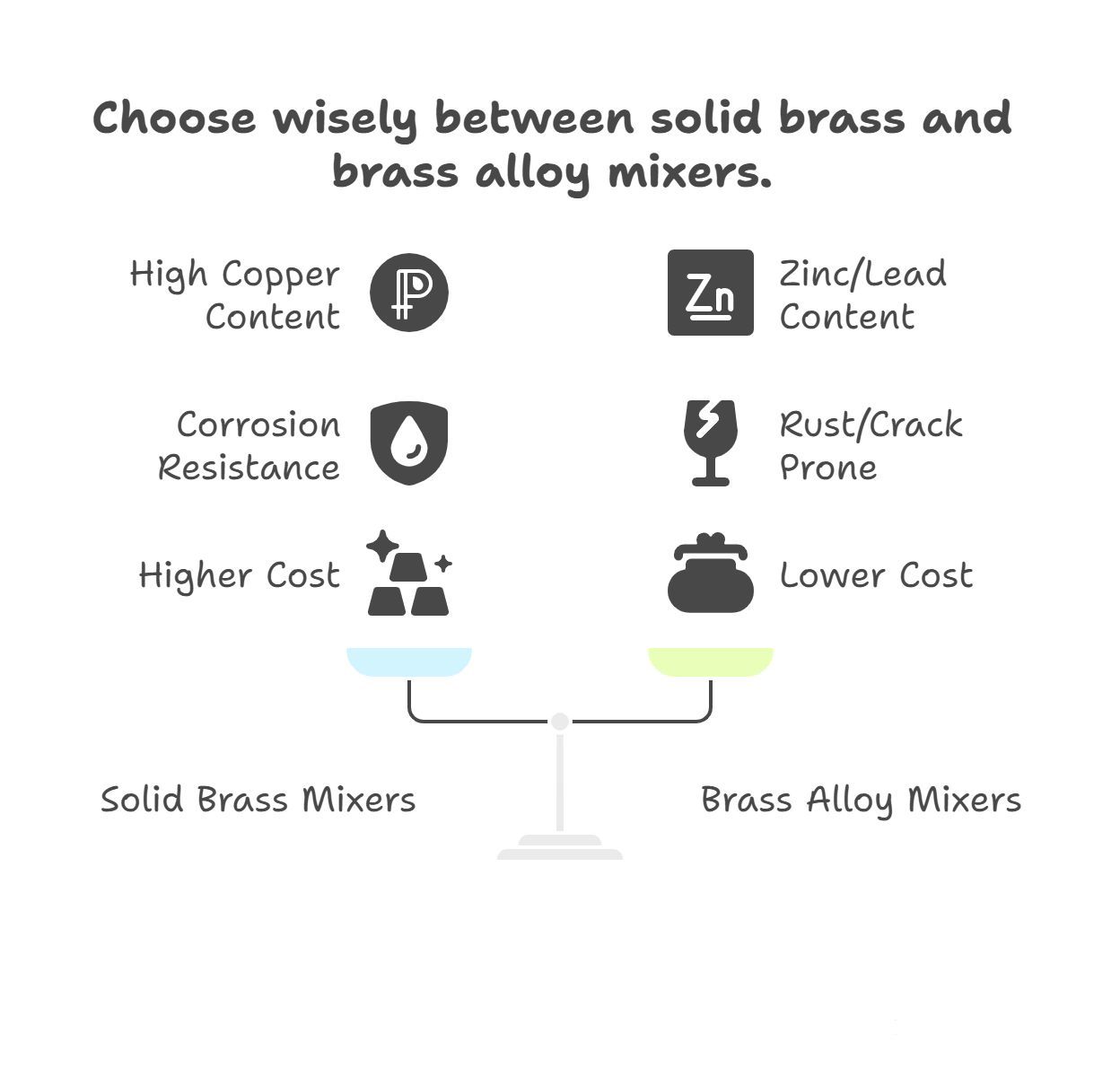

Many buyers don't set clear standards for shower hardware. Take mixers, for example,they can be made of plastic, brass, or stainless steel. Even with 'brass,' there's a big difference between solid brass and brass alloy. If you just tell a supplier 'I need a brass mixer,' quotes can vary by 30% or more. The reason? Vague specs.

Solid brass mixers are nearly 100% copper, highly resistant to corrosion, and built for long-term use,great for mid-to-high-end projects.

Brass alloy mixers contain zinc, lead, or other metals. They're cheaper but less durable, and may rust or crack after a few years in damp conditions.

Therefore, you need to have a systematic knowledge of materials. The common types of materials are listed below:

Common Materials in Shower Hardware

| Material Type | Material | Key Features | Typical Use |

Plastics | ABS | Low cost, easy to mold | Hand shower handles, casings |

PVC | Corrosion-resistant, not heat-resistant | Drain pipes, small parts | |

Nylon (PA) | Strong, tough | Load-bearing parts, rollers | |

Metals | Brass | Durable, corrosion-resistant | Mixers, faucet bodies |

| Stainless Steel 304 | Rust-proof, food-grade | Hoses, shower support bars | |

| Zinc Alloy | Low cost, easy to cast | shower handles, hand showers | |

| Others | Ceramic | Wear- and heat-resistant | Faucet cartridges |

Silicone | Silicone Flexible, heat-resistant Seals | Seals |

Factory Audit & Background Check

In China, shower accessory suppliers range from small workshops with a few dozen workers to factories producing millions of sets a year. The gap in quality can be huge, so vetting suppliers is essential.

What to check:

Business license & registered capital

Larger capital and longer history usually mean more stability.

Expo participation

Canton Fair: China's largest export fair; long-term exhibitors are usually export-savvy.

BAU Trade Fair:German Building Materials Fair,exhibitors are typically large-scale manufacturers with strong R&D.

ISH :(Frankfurt, Germany),Focused on bathrooms and HVAC, exhibitors here usually have strong technical and design capabilities.

Export markets

If a supplier has never shipped to your country, they may lack knowledge of local certifications or customs requirements (like CE, WRAS, etc.), which can cause clearance issues.

Field inspection of the factory should focus on

1. After entering the factory, field check whether the production equipment is automated.

2. Is the quality inspection process perfect? (Incoming material inspection, semi-finished product inspection, full inspection before shipment)

3. Is the storage environment dry and moisture-proof?

When necessary, use an independent testing agency to check the factory.

Samples & Quality Checks

Sampling is the key step to avoid big losses later. The good news? You can do some simple checks yourself,no fancy equipment needed. Here are a few practical tricks:

Batch-marked samples

Ask the factory to mark batch numbers on samples. This ensures the bulk order comes from the same production batch.

Quick material checks

Magnet test: 304 stainless steel is almost non-magnetic, while iron or nickel-plated parts will stick.

Weight test: Solid brass feels noticeably heavier than zinc alloy.

Plating corrosion test

No need for a 48-hour salt spray test. Just drop a bit of saltwater on the surface overnight. A good accessory shouldn't rust within 1–2 days.

Plating adhesion test

Stick a piece of tape (3M works best) firmly on the surface, then rip it off. If the coating peels easily, the process isn't up to standard.

Valve & handle durability

Simply turn them on/off dozens of times. A smooth feel means good quality; sticking or leaking is a red flag.

Seal & hose check

Stretch a seal, soak it in hot water, then cool it down. If it bounces back, it's fine. For hoses, twist or pull gently; poor ones deform or leak quickly.

Shipping & Packing Control

Shipping is another stage where problems often occur. Common issues include plated parts rusting during sea transport, glass or ceramic pieces breaking, or cartons getting crushed and causing returns.

Typical protection measures:

Plated parts (faucets, support bars): Add moisture-proof bags or desiccants inside the box.

Stainless steel hoses: Seal each one in plastic to prevent scratches.

Shower valves: Use foam or pearl cotton for cushioning.

Also, make sure carton strength is specified. For example, a 5-layer corrugated carton should handle a stacking strength of ≥ 250 kg.

After-Sales & Long-Term Partnership

Here are the most common after-sales issues with shower fittings:

Plating shows rust spots within a year.

Hoses leak or burst.

Slow response from the factory once payment is made.

Every order feels like a renegotiation, with no long-term framework.

How to solve it:

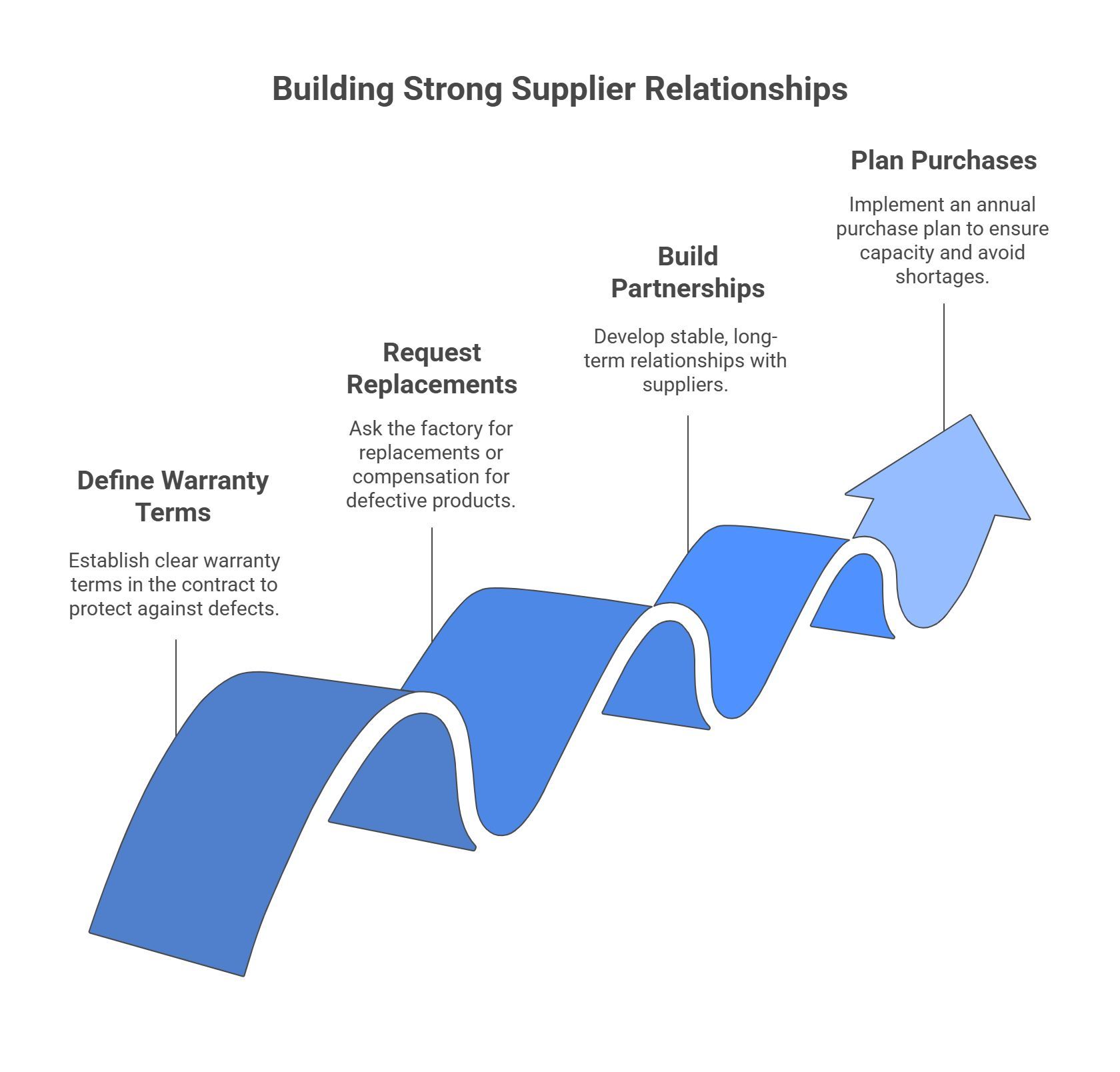

Define warranty terms in the contract (usually 12–24 months).

Ask the factory to provide replacements or compensation for defects.

Build stable, long-term partnerships instead of switching suppliers often.

Consider an annual purchase plan so the factory reserves capacity, avoiding shortages in peak season.

In the long run, a solid supplier relationship helps you keep delivery and pricing stable, even when raw material costs or exchange rates fluctuate.

FAQ: Common Questions About Shower Enclosure Hardware

What's the most common issue in bulk orders?

Samples and mass production don't match.

What you must do is: ensure the sample standards are explicitly stipulated in the contract and require random inspections of the bulk goods.

The factory says they're 'ISO certified.' Can I trust it?

ISO only proves management systems, not product quality. Always combine it with real product testing.

Is a small trial order safer?

Yes. Keep the first order small to test the factory's stability, then scale up once proven.

What if quality issues appear?

Have clear terms in the contract: return, replacement, or compensation mechanisms.

Final Thoughts

Review these 5 key points and stop managing shower hardware sourcing with just surface-level checks. Most risks can be avoided if you take control early.

In short, it's about being proactive, not reactive. That's the right way for international buyers to source effectively in China.

At Hydrorelax, we've been in this industry for over 20 years, serving customers across Europe and North America. We know the local standards and provide a true one-stop solution,from design, production, and testing to shipping and after-sales.

If you're looking for a reliable supplier in China or want to streamline your current supply chain, feel free to contact us. We're happy to share our experience, help reduce risks, and improve efficiency.